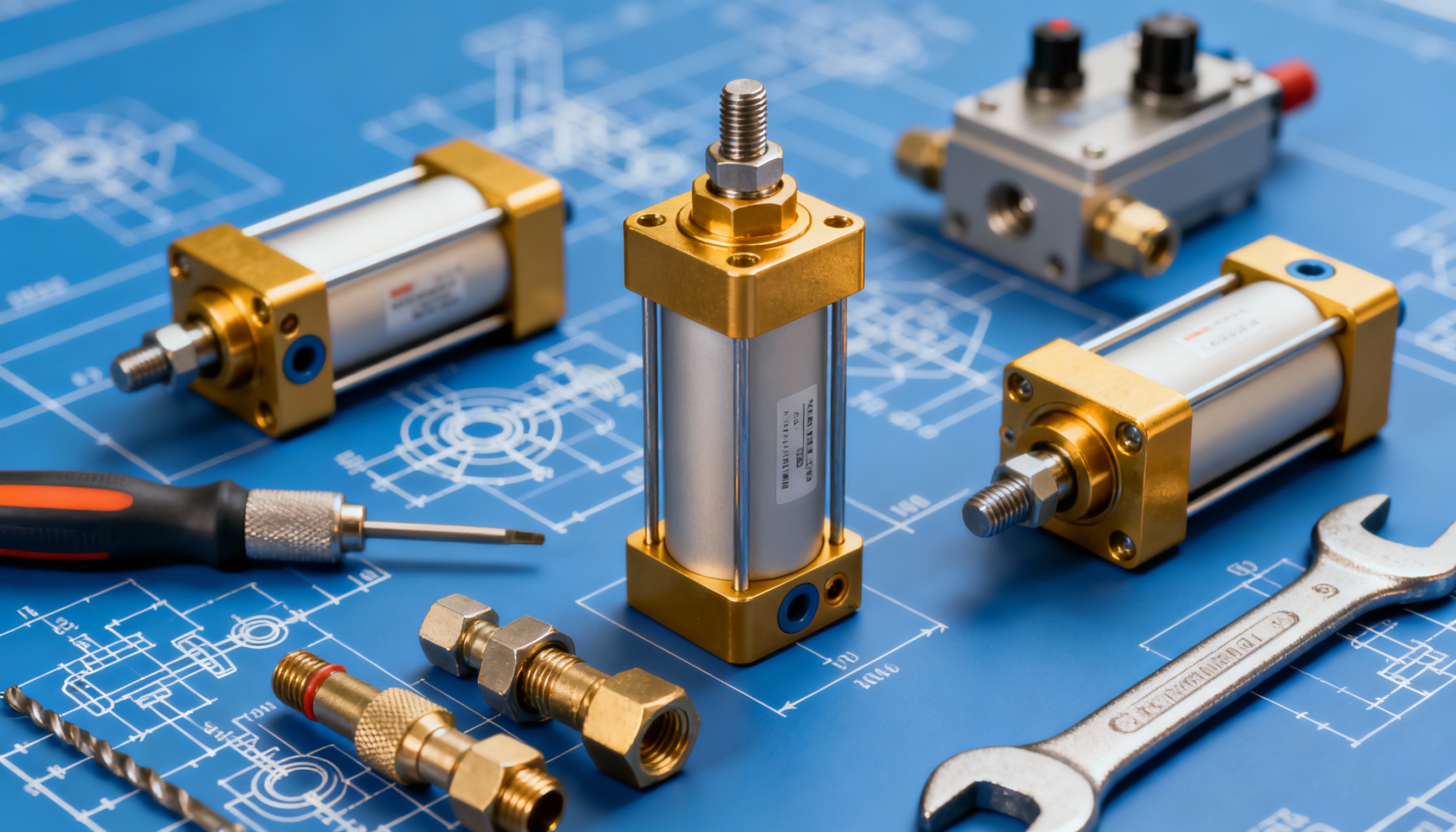

In today’s times, imagining a world without pneumatic components is impossible. They are found almost everywhere – from the food industry to the automotive industry. They are an excellent choice for tasks that require accuracy and speed. They are vital for any industry, as they keep the operations seamless. Some of the basic pneumatic components include pneumatic tools, air cylinders, pneumatic actuators, and more. If you are a business owner looking for pneumatic components, your choice can make or break your business operations.

This blog will guide you in choosing the right pneumatic components based on your business needs. Let us talk more about it.

What Is Pneumatics and Why Is It Important?

Pneumatics involves the use of compressed air to perform work. It finds application in numerous industries such as manufacturing, automobile, construction, and food processing. Machines can be operated by using pneumatic parts, which transfer compressed air into motion, whether in a straight direction (linear) or circular motion.

There are benefits of pneumatics, which include:

- Economical: Pneumatic systems are often less expensive to install and maintain compared to hydraulic systems or electric systems.

- Speed: Pneumatic systems are highly mobile and hence suitable in operations that are fast-paced.

- Easy to operate: There are fewer components of a pneumatic system, and they are less difficult to maintain.

- Safer: The air-powered tools are safer than electric or hydraulic systems that may pose fire hazards.

When selecting pneumatic components, you need to consider what you need, the amount of power needed, the space available, and operating conditions.

Selection of the Pneumatic Cylinders.

A pneumatic system requires Pneumatic Cylinders as important components. They convert compressed air to straight-line motion (push or pull). These types of cylinders find application in activities such as lifting, pressing or moving things. In selecting pneumatic cylinders, the following are the key considerations:

- Bore size: The bore size determines the level of force that the cylinder can generate. The larger bores are more powerful and might require increased air pressure and equipment size.

- Length of stroke: This is the distance of the movement of the piston. One should make a selection of a cylinder that has the correct stroke length that corresponds to the requirements.

- Cylinder type: Cylinders of various movements are in existence.

For example:

The single-acting cylinders involve the use of a spring to put the piston back at its starting point.

The double-acting cylinders rely on air pressure to lengthen and shorten the piston.

What is Pneumatics and Why Is It Important?

Pneumatics uses compressed air to do work. It’s used in many industries like manufacturing, automotive, construction, and food processing. Pneumatic components turn compressed air into motion, either moving in a straight line (linear) or rotating, so machines can perform tasks.

Some advantages of using pneumatics include:

- Cost-effective: Pneumatic systems are usually cheaper to install and maintain than hydraulic or electric systems.

- Speed: Pneumatic systems can move quickly, which is great for fast-paced operations.

- Simple to use: Pneumatic systems have fewer parts and are easier to maintain.

- Safer: Air-powered tools are safer than electric or hydraulic systems, which can have fire risks.

When picking pneumatic components, it's important to think about your specific needs, the power required, how much space you have, and the operating conditions.

1. Choosing the Right Pneumatic Cylinders

Pneumatic cylinders are key parts in a pneumatic system. They change compressed air into straight-line motion (push or pull). These cylinders are used for tasks like lifting, pressing, or moving things.

When choosing pneumatic cylinders, here are the main things to consider:

- Bore size: The bore size determines the amount of force the cylinder can produce. Larger bores give more power but may need higher air pressure and larger equipment.

- Stroke length: This refers to how far the piston can move. It’s important to choose a cylinder with the right stroke length to match your needs.

- Cylinder type: There are different types of cylinders for different movements. For example:

- Single-acting cylinders use a spring to return the piston to its original position.

- Double-acting cylinders use air pressure to extend and retract the piston.

|

Type

|

Description

|

Ideal Use Case

|

|

Single-Acting Cylinder

|

Uses a spring to return the piston.

|

Low-force applications, short strokes.

|

|

Double-Acting Cylinder

|

Requires air pressure for both directions.

|

High-force applications, longer strokes.

|

|

Rodless Cylinder

|

No external rod; the piston moves along a rail.

|

Limited space, precise linear movement.

|

|

Guided Cylinder

|

Built with a guide for more stable motion.

|

Heavy-load applications require stability.

|

Each of these options comes with its own advantages and limitations, and selecting the right type is crucial for meeting your performance criteria.

2.Choosing Pneumatic Actuators

Pneumatic Actuators Valve are components that convert compressed air into mechanical motion. While pneumatic cylinders are for linear (straight-line) movement, actuators can do both linear and rotary (rotating) movements.

When selecting pneumatic actuators, keep these factors in mind:

- Torque requirements: For rotary actuators, think about the force (torque) needed for the movement.

- Speed: You can adjust the speed of pneumatic actuators, so make sure you choose one that fits your operation's speed needs.

- Load capacity: Make sure the actuator can handle the weight of the object it will move.

Pneumatic actuators are essential for a variety of processes, especially in systems where flexibility and movement precision are required.

|

Type

|

Description

|

Ideal Use Case

|

|

Rotary Actuators

|

Provides rotary motion.

|

Assembly lines, robotics, turntables.

|

|

Linear Actuators

|

Provides linear motion.

|

Material handling, presses, conveyors.

|

|

Tie-Rod Actuators

|

Compact design with threaded rods.

|

Small, space-constrained environments.

|

|

Pneumatic Grippers

|

Used to grasp and manipulate objects.

|

Pick-and-place applications, robotics.

|

3. Choosing Pneumatic Tools

Compressed air pneumatic tools are applied in industries in processes such as drilling, sanding, and tightening of bolts. These are tools that are characterised by speed and efficiency.

The following are some of the considerations that should be made when selecting pneumatic tools:

- Air pressure: Make sure that the tool will operate in the air pressure of your system.

- Size and weight: Select tools that are convenient to the workers and do not make them fatigued when using them.

- Durability: Pneumatic tools must be hard because they are utilised in high-demand situations.

4. Air Preparation and Support Equipment.

Other equipment such as filters, regulators, and lubricators (FRLs) may be included in pneumatic systems besides the primary components, such as pneumatic cylinders and actuators, which are important in maintaining a healthy pneumatic system.

- Filters: These are used to purify the compressed air that might have dirt or debris that will harm your components.

- Regulators: They regulate the pressure of the air, and they ensure that components are not exposed to excessive pressure.

- Lubricators: These are used in order to put oil on so that the system runs smoothly and to ensure that the moving parts are not worn out.

5. Material and Environmental Concerns.

The environment in which you will put your pneumatic system also should be considered by you. To elaborate, in case your equipment will be subjected to heat, moisture and harsh chemicals, then you must select materials that can withstand these circumstances.

Here's what to consider:

- Corrosion resistance: In case water or chemicals are going to be exposed to your system, be sure to use parts made of water resistant materials such as stainless steel, which does not rust or corrode.

- Resistance to temperature: ensure that your components are constructed to withstand a high or low temperature depending on your working conditions.

- Dust resistant: When working in a dusty atmosphere, you will require parts that have good seals that will avoid dust entering into the parts and destroying them.

6. Experience and Assistance of Suppliers.

You should choose a supplier that is good, and who realizes your business and what you require. Not only can a good supplier provide parts, but also good advice and constant assistance.

When selecting a supplier, use:

Experience in the industry: the supplier can be able to guide you in the type of parts to use in your system.

-

Availability: Ensuring that the supplier is able to supply parts fast enough to ensure that your system is online.

-

After sales services: A proper supplier will assist you in troubleshooting, maintenance guidance and employee training.

FAQs:

Q1.What is the correct way to select the pneumatic cylinder to use in my application?

You must know what you need to do, and should know that before all. Understand whether you require a single-acting cylinder, a double-acting cylinder, the amount of load is required etc.

Q2. What is the difference between the pneumatic actuators and cylinders?

The fundamental distinction between Pneumatic cylinders and pneumatic cylinders is in their movement. On the one hand, pneumatic actuators provide both - linear and rotary motion, whereas pneumatic cylinders provide only one - linear motion.

Q3. What is the correct method of selecting the appropriate pneumatic tool?

Some of the factors to be put into consideration before deciding to invest in pneumatic tools are as follows:

-

Air requirement

-

Tool's Size

-

Tool's Weight

-

Durability

Q4. What use do filters and regulators have in pneumatic systems?

A pneumatic system has filters and regulators as a significant component. To ensure that the components are always dust-free, filters are important. On the same note, the regulators will be essential in making sure that the pressure of air is controlled. Without any regulators, machine parts can get spoilt in case the pressure is considerable.

Q.5 My business operations occur in extreme weather conditions? Will your pneumatic tools play on such occasions?

Yes. V.S. Pneumatics has a variety of solutions that may be applied in case of high temperatures. We would like you to access our web site and select goods that may easily deal with extreme conditions such as heat, chemicals etc