One of the most valuable components of modern automation systems that utilise robotics is the pneumatic gripper. Pneumatic grippers, also known as parallel jaw grippers, assist with a wide variety of tasks, such as material handling, assembly, and pick-and-place tasks. There are various types of grippers available in the market, out of which parallel grippers are most widely used. Among the different types of grippers, parallel grippers are the most widely used — known for their accuracy, effortlessness, and flexibility.

In this blog, we will talk all about parallel grippers – how they work, their types, and their benefits.

What Is a Parallel Gripper?

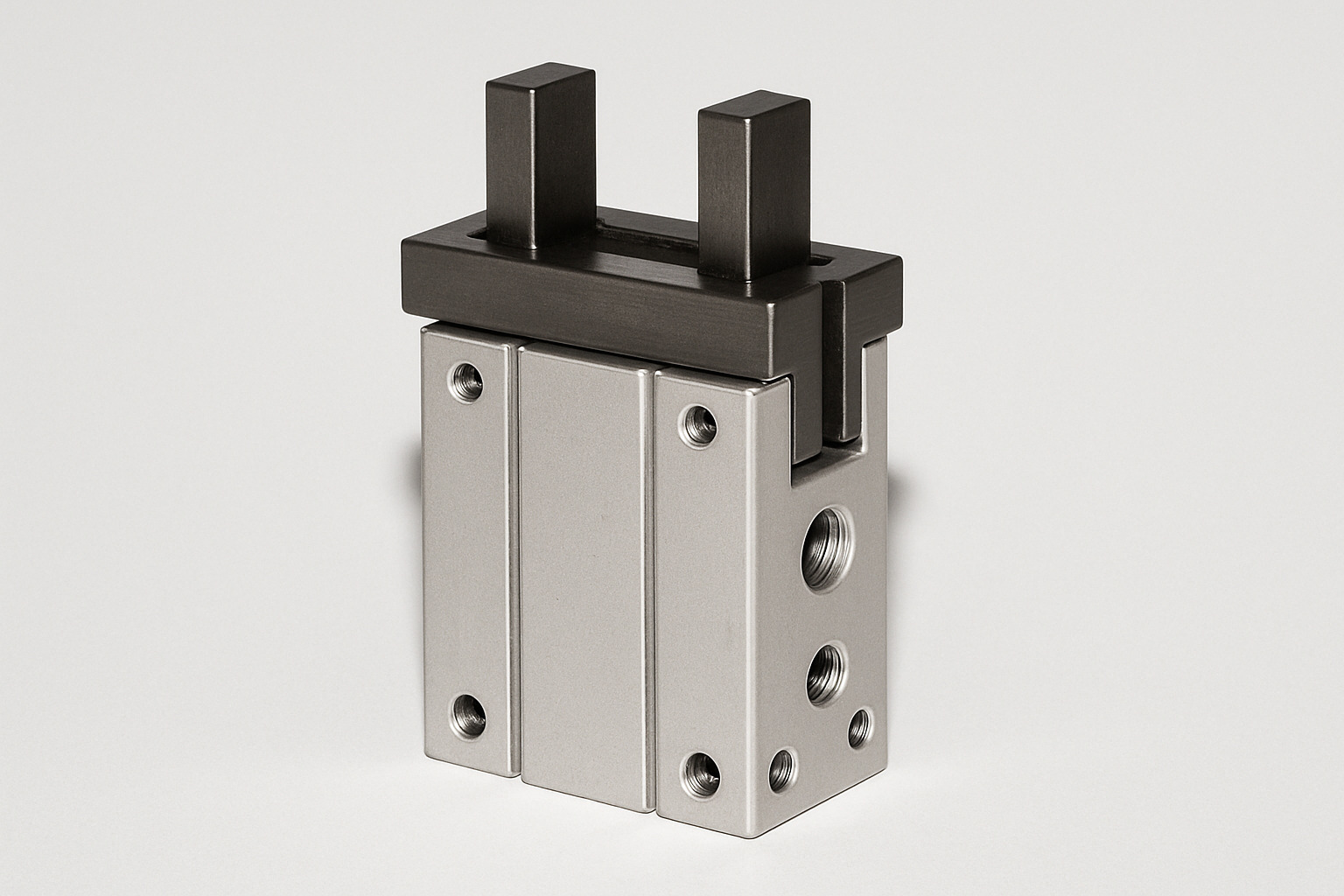

A parallel gripper is a mechanical device that uses two jaws (or fingers) moving in parallel to each other in order to grip or release a part. In contrast to angular or adaptive grippers, the jaws of a parallel gripper do not rotate; the gripper jaws move in a linear fashion, also known as straight-line motion, while maintaining their parallelism. This gives parallel grippers the ideal capability of grasping parts of a uniform shape and size, such as cylinders, blocks, or machined parts. Parallel grippers are frequently powered by pneumatic forces; however, they can also be electric or hydraulic, with the precision and force being the determining factors.

V.S. Pneumatics is amongst the best parallel gripper manufacturers in Noida. Contact us today!

How Does a Parallel Gripper Work?

Most pneumatic parallel grippers use a piston mechanism to connect the jaws together through the use of linkages or cam mechanisms or direct drive. Here is a simplified version of a common example:

Air Supply: Compressed air enters the cylinder chamber.

Potential Movement of the Piston: The air pressure can move the piston in a fore or aft direction.

Action of the Jaws: The piston is connected to the jaws through linkages that convert the linear motion of the piston to open and close the jaws.

Gripping: When the jaws open, they are gripping onto some object. When the jaws move outward, they will let go of the object.

In a double-acting parallel gripper, air is made to alternate between opening and closing the jaws. In single-acting designs, air will create the action, which in this case should be to close, and a spring will return the jaws to open.

Types of Parallel Grippers

Based on their construction, there are several types of parallel grippers. Below are the most common types.

1. Pneumatic Parallel Grippers/ Parallel Jaw Grippers

Actuated by compressed air.

They provide a robust gripping force with a quick actuation speed.

Ideal for industrial automation applications, packaging, and in machine tools.

Pros:

- Fast

- Cost-effective

- Simple Design

- Cons:

- Requires air supply/maintenance

- Not as precise as electric types.

2. Electric Parallel Grippers

- Driven by a compact electric motor instead of air.

- Offer great control due to its gripping force, speed, and position.

- Common in robotics, electronics assembly, and delicate part handling.

Pros:

High precision and repeatability

Adjustable force and stroke

Clean operation (no air)

Cons:

More expensive

Slower actuation speed than pneumatic grippers

3. Hydraulic Parallel Grippers

- They use hydraulic pressure for extremely high gripping forces.

- They are suitable for heavy-duty applications, including automotive, forging, or foundry automation.

Pros:

Great grip strength

Durable for harsh environments

Cons:

Complex maintenance

Not suitable for small or delicate components

4. Two-Finger vs. Three-Finger Parallel Grippers

- Two-finger grippers: They are the standard type, ideal for gripping symmetrical parts.

- Three-finger grippers: They are used when it is important to center cylindrical objects

Construction and Key Components

A typical parallel gripper includes:

|

Component

|

Function

|

|

Body (Housing)

|

Holds internal components; made of aluminum or steel.

|

|

Jaws/Fingers

|

Contact the workpiece to hold it firmly.

|

|

Piston

|

Converts air pressure into motion.

|

|

Linkage Mechanism

|

Translates piston motion into parallel movement.

|

|

Seals & Bearings

|

Maintain air pressure and smooth operation.

|

|

Mounting Base

|

Used to attach the gripper to a robot arm or fixture.

|

Important Factors to Consider When Buying Parallel Grippers

When choosing a parallel gripper, several parameters determine performance:

|

Specification

|

Description

|

|

Stroke

|

Distance each jaw moves.

|

|

Grip Force

|

Maximum holding force (usually in N).

|

|

Repeatability

|

Precision in jaw positioning for repeated operations.

|

|

Operating Pressure

|

Air pressure range (for pneumatic models).

|

|

Weight

|

Impacts robot load capacity.

|

|

Actuation Time

|

Speed of opening/closing.

|

|

Mounting Style

|

Side, bottom, or front mount depending on your system.

|

Accessories and Components Used with Parallel Grippers

To enhance functionality, parallel grippers are often combined with:

- Finger Extensions or Custom Jaws – For specific shapes or soft materials.

- Sensors – Detect part presence or confirm grip (reed switch or magnetic sensors).

- Rotary Actuators – Combine rotation and gripping in one motion.

- Linear Slides – For additional reach or travel.

- Mounting Brackets – To integrate with robot arms or machines.

Applications of Parallel Grippers

Parallel grippers, also known as parallel jaw grippers, are used across many industries, including:

1. Automation & Robotics

- Pick-and-place operations

- Assembly lines

- Machine tending and part transfer

2. Electronics & Semiconductor

- Handling delicate circuit boards and components

- Precision placement of micro parts

3. Automotive Industry

- Handling metal components

- Loading/unloading machine tools

- Component assembly

4. Packaging & Logistics

- Gripping boxes, bottles, or containers

- Sorting and transfer systems

5. Medicinal

- Handling syringes and other components

- Clean, oil-free operations (for electric grippers)

Looking for parallel grippers in Noida? We have got you covered.

Parallel Grippers vs. Angular Grippers

|

Feature

|

Parallel Gripper

|

Angular Gripper

|

|

Jaw Motion

|

Linear (parallel)

|

Rotational (angular)

|

|

Best For

|

Cylindrical, uniform parts

|

Irregular or large parts

|

|

Precision

|

High

|

Moderate

|

|

Space Requirement

|

Compact

|

Requires more clearance

|

|

Maintenance

|

Low

|

Slightly higher due to pivots

|

Advantages of Using Parallel Grippers

- Simple and Compact Design – Easy to install and maintain.

- High Repeatability – Ideal for automated systems needing precision.

- Fast Operation – Especially in pneumatic versions.

- Versatile Mounting Options – Can be installed in any orientation.

- Cost-Effective – Affordable compared to adaptive or servo-based grippers.

Limitations

- Not ideal for irregularly shaped parts.

- Limited stroke compared to other gripper types.

- Pneumatic versions require an air supply and control valve.

How to Select the Right Parallel Gripper

The following pointers will help you in selecting the right parallel gripper:

- Part shape and size: Check if the gripper jaws can fully close around the part.

- Grip force requirement: You should maintain the weight of the part with a safety factor (usually between 2 and 3).

- Environmental conditions: Choose only the suitable material type

- Mounting orientation: The part could be mounted either vertically or horizontally or otherwise.

- Level of automation: Use pneumatic grippers when you need high speed and electric grippers when you need precision.

Equipment Care Tips

- Check for leaks in air lines and seals regularly.

- Keep the jaws clean and lubricated (except for cleanrooms).

- Balance sensors at fixed intervals.

- Check that mounting screws are tight to avoid misalignment.

Conclusion

Parallel gripper are an essential component for databases and robotic handling systems. Their simple design, efficient footprint, and robust performance make them an ideal product for infinite automation applications, from precise assembly to high-speed packaging. Whether you're an engineer working on a robotic arm or a plant manager considering your next operational improvement, you should explore a quality parallel gripper for smoother operations, a longer life for your equipment, and improved productivity.

If you are looking for parallel grippers in Noida, contact V.S. Enterprises today. They are ready to help you discover pneumatic grippers and automation accessories from brands such as Janatics, Festo, and SMC-providing proven performance and quality in all industrial applications.