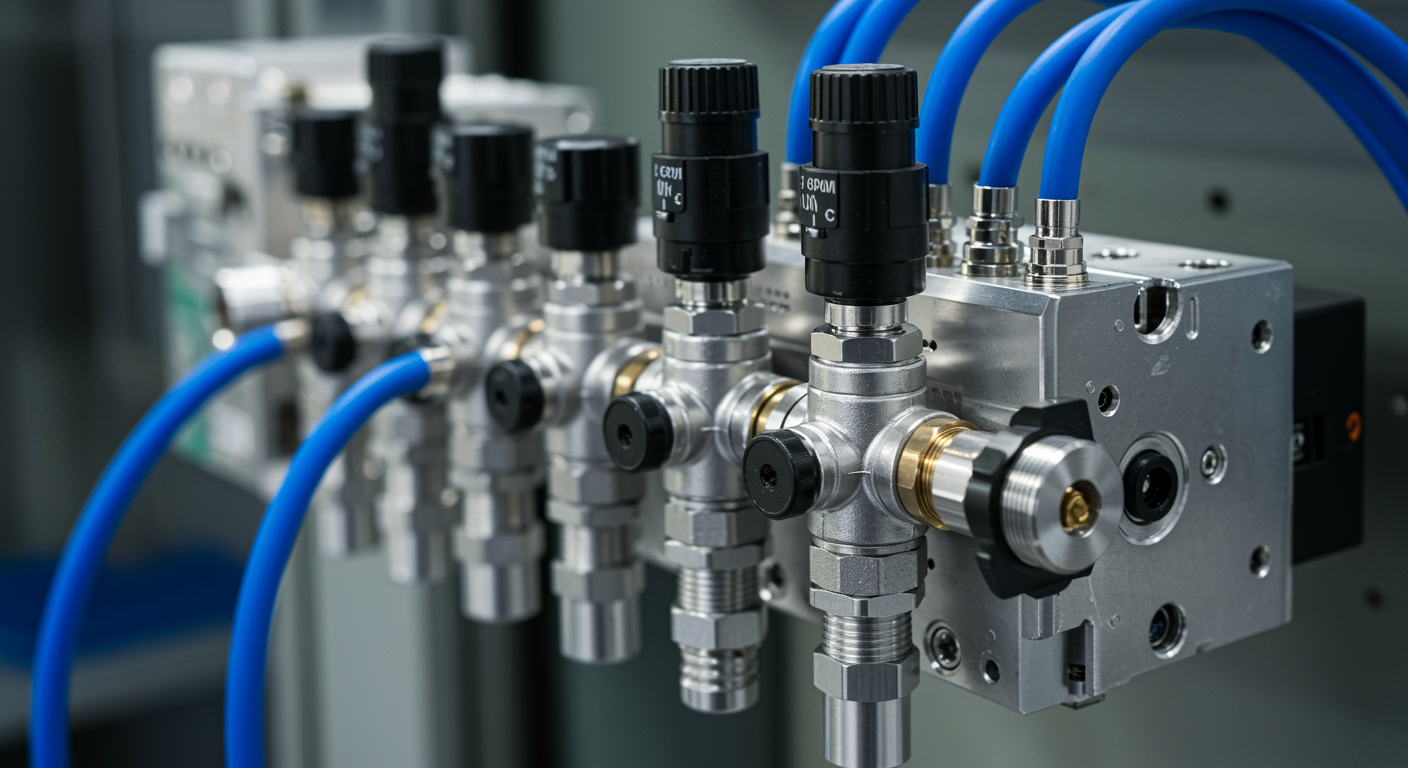

Pneumatic systems have been vital in the manufacturing environments in attaining precision, reliability and automation. Compressed air is used to operate a host of machines and tools in terms of packaging, material handling.

Pneumatic valves dictate the flow, direction, and pressure of air. Proper choice of the valve may significantly enhance efficiency and safety. Being one of the major manufacturers of pneumatic products in India, we have witnessed the optimization of performance of pneumatic products in the various industries once paired correctly, cylinders and valves. It is an informative guide on the 10 best kinds of pneumatic valves that every plant should be familiar with – and the professional advice on which type to utilize at what time.

What Are the 10 Types of Pneumatic Valves?

Here are the 10 types of Pneumatic Valves, their applications, and expert tips.

1. Solenoid Valves – Accuracy and Automation in a Single Valve.

What are they?

These valves use magnetic coils to function. They are powered by electricity used to open and close air channels. They are widely used in machine automation.

When to Use?

- Applicable in regulating pneumatic cylinders in an automated assembly line.

- Ideal for packaging, bottling, and sorting machinery that needs time accuracy.

Expert Tip

Select superior quality coils and enclosures in dusty or humid Indian climatic conditions.

2. Directional Control Valves - guiding the flow.

What are they?

Directional control valves (DCVs) control the flow of compressed air through a circuit, which ports admit or exhaust air.

When to Use?

- Important in systems that have several pneumatic cylinders in use.

- Mostly used in conveyor lines, robotics, and pick-and-place systems.

Expert Tip

In case of double-acting cylinders, a 5/2-way or a 5/3-way setup is preferable to have the best level of control.

3. Flow Control Valves – Speed and Performance Adjustments.

What are they?

Flow control valves modify the rate of air flow, which has a direct influence on the speed of the actuator. Correct adjustment of speed eliminates jumpy or rough engine movement.

When to Use?

- Application in machines that require repetitive motion, e.g., press or seal machines.

- A requirement of systems with sensitive or high-precision-driven types of pneumatic valves.

Expert Tip

To be able to adjust the flow control valves properly, it is always best to install them near the actuator.

4. Check (Non-Return) Valves – Stalling Backflow.

What Are They?

When the machine requires the movement of flow in a specific direction, non-return valves are used.

When to Use?

- To avoid the loss of pressure in complicated circuits.

- Essential in systems that are connected to several air supplies or compressors.

Expert Tip

Have them in a partnership with manufacturers of trusted pneumatic products to avoid compromising on the quality of the material and leak-proof service.

5. Quick Exhaust Valves - To be Faster Actuated.

What are they?

Quick exhaust valves bypass the control system and release air straight to the atmosphere.

When to Use?

- Ideal in those applications where the pneumatic cylinder actuation is required to be quick, including stamping, clamping, or PET molding.

- Increases the speed of the cycles and minimises the reaction time.

Expert Tip

You can locate them close to the actuator to reduce lag and pressure drop.

6. Pressure Relief Valves Safety You Can Count On.

What are they?

Safety valves automatically open when there is too much pressure in the system to prevent any damage or failure.

When to Use?

- Where constant pressure is very important.

- Particularly important when there is more than one compressor or air storage tank.

Expert Tip

Relief valves should always be checked during regular maintenance procedures.

7. Manual Valves: Simple, Dependable Control.

What are they?

Valves are manually or foot-operated and are used to directly control air when it is not vital to automate.

When to Use?

- When configuring, calibrating or maintaining pneumatic cylinders.

- In the case of emergency shutdowns or manual overrides.

Expert Tip

Select operator-friendly and safety-enhancing ergonomic designs of levers or pedals.

8. Shuttle Valves – Dual-Source Performance.

What are they?

The shuttle valves enable the two inlets to be passed through a single outlet, enabling the more pressurised source to automatically select.

When to Use?

- Where there is a need to have backup air sources in redundant control systems.

- Applicable in safety circuits and in dual control.

Expert Tip

If you want to prevent the valve sticking, use clean and dry air.

9. Pilot Valves – in charge of the Controllers.

What are they?

Larger valves or other complex assemblies are operated by little air signals on pilot valves.

When to Use?

- Where large pneumatic cylinders or high flow are required.

- When direct valve control is not easy because of space limitations.

Expert Tip

Mount them to the main valve. This minimises waiting time.

10. Angle Seat Valves, Long Life, High Flow.

What are they?

The angle seat valves come with high flow capacity and durability, which are suitable for continuous-duty operations.

When to Use?

- Usually in food, pharmaceutical and chemical processing plants that demand hygiene and resistance to corrosion.

- Appropriate for hot air, steam, or gas control.

Expert Tip

To be as reliable as possible, it is better to use a stainless-steel construction offered by well-known manufacturers of pneumatic products.

Best Practices for Choosing Pneumatic Valves

1. Understand Your Application

Each process demands specific pneumatic valve types — from solenoid valves for automation to flow controls for precision.

2. Collaborate with Trusted Manufacturers

Choosing Pneumatic Product Manufacturers like V.S. Enterprises ensures complete transparency and personalised client support and after-sales services.

Conclusion

Understanding and identifying the optimal pneumatic valve types can be the secret to your success in automating your integrations. Each has a purpose, from safety to precision control, all of which lends itself to the optimal performance of an automation system. It does not matter if you are updating an old pneumatic valve or opting for a new one; partnering with leading pneumatic manufacturers like V.S. Enterprises ensures that you get the best pneumatic solutions for your business.

FAQs

1. What type of pneumatic valves are most common?

All types of pneumatic valves are used in various industrial applications. Out of all these, solenoid valves and directional control valves are the most commonly used types of valves. Since both of them are extremely flexible, they are preferred by many plant owners.

2. What factors should I keep in mind before selecting a pneumatic cylinder valve?

Before you decide to buy a pneumatic cylinder, there are certain factors that you should take into consideration. Some of them are as follows:

- The size of the cylinder

- The speed of the stroke

- The needed range of pressure

3. How can I maintain pneumatic valves?

Routine maintenance is vital to ensure that your machine works well at all times. When left unchecked, your machine may give way to wear and tear. Here are some of the ways that will ensure your pneumatic system remains fully functioning:

- Check for leaks on a regular basis

- Clean the filters daily

- Lubricate the machine parts regularly

4. Can pneumatic valves be used at higher pressures?

Yes. Some of the high-pressure-rated pneumatic valves can be used at high pressure. You just have to ensure that you source the solution from a reputable manufacturer. V.S. Pneumatics is a proud pneumatic products manufacturer in Noida. Contact us today.