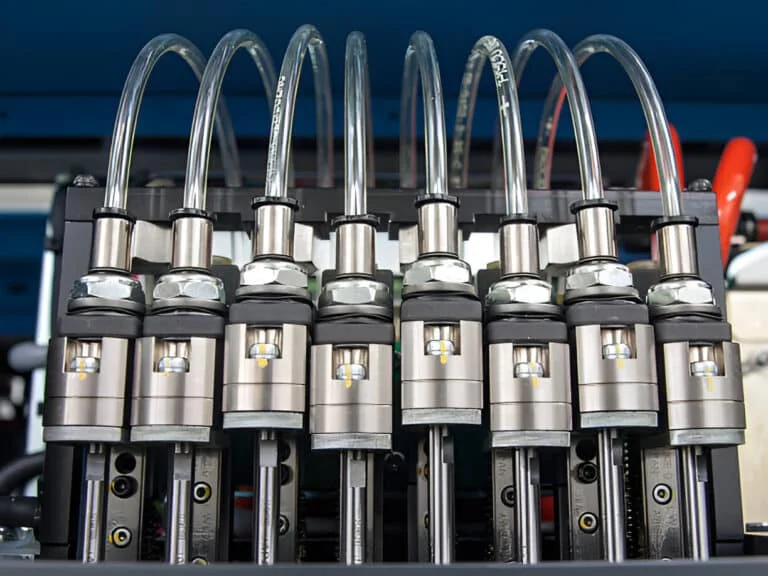

Pneumatic cylinders are an important part of the automation industry, material handling and heavy machinery. It converts pressurised Air into mechanical motion thus, generating pneumatic power. In a pneumatic system selecting the right pneumatic cylinder for use is suggested to further increase efficiency, durability and performance of the pneumatic system. There are many designs available in the market with each one serving its own purpose. For optimal performance selecting a suitable cylinder corresponding to your application is necessary. In this guide we will discuss the main factors of choosing a pneumatic cylinder. We will discuss their different types, functions and how to choose the best cylinder for your requirements. It is not hard to find reliable pneumatic systems within such a vast market. But finding reliable dealers with quality products and good after sales services is not that easy. VSpneumatic is present with the vision of safer industry processes in all over India.

What is a pneumatic cylinder and how does it operate?

Pneumatic cylinders are main components of the pneumatic systems. They are an intrigue machine consisting of a piston in a closed chamber which is powered by pressurised Air. For different industrial needs different kinds of piston moments are possible: Linear or rotational. These cylinders are used because they are cost effective, efficient and can be operated even in harsh environmental conditions without overheating. Selecting the right pneumatic cylinder depends on factors like the cylinder’s force output, speeds, stroke length. Only after considering all these factors can you get yourself the most suited cylinder for your needs.

Advantages of using pneumatic cylinders:

- They are efficient in saving energy. They used compressed air as a power generation source which is available at all times easily.

- They are quite durable and can withstand harsh climates for longer durations.

- They are fast and light which ensures rapid movements for industrial works.

- They are safer than hydraulic cylinders as they don’t have hazardous leaks and risk of explosions.

Types of Pneumatic cylinders with their application

Single acting cylinders

These are common types of cylinders. They use compressed air as a means to extend pistons in a single direction and it relies on springs for the piston to return back. Single acting cylinders are designed simply and they are cost effective. They are also popular for their efficient energy expenditure. Only issues with these are that their force generation is limited and movement control is quite hard. These are the common systems in which single cylinders get used.

- Pneumatic presses – These are used in presses for stamping and pressing work. High force is not needed for press work.

- Clamping devices – Such devices are quite common in Automotive industries and assembly lines.

- Automated doors – With limited application of doors a single acting cylinder is more than enough for controlled opening and closing mechanisms.

Double Acting cylinders

This cylinder uses air for both extension and retraction of the piston enclosed in a cylindrical shaped tube. This can generate more power and offer more force capacity. This cylinder also offers greater precision and movement control than a single acting cylinder. That’s why these cylinders are more useful in complex automated movements.Issues with this cylinder are that its design is quite complicated and they are more expensive. These are the uses of these cylinders:

- Material handling – With its highest power output and controlled movement works like heavy material handling with precision is possible.

- Industrial automation – In industrial automation process this cylinder can be found gettin used in assembly lines

- Pneumatic robotic arms – robotic arms require higher precision and different movements for that these are more suitable.

Rodless cylinder

A piston is not used in these cylinders. They eliminate the need of a moving piston as a cylinder to generate power; they directly use pressurised air for application. They are ideal for places with less space. Because of their compact design even in less space these cylinders work well and are capable of long strokes generating smoother power. This system requires higher investment for setup and requires precise alignment for proper function. Typical applications of rodless cylinders:

- Conveyor systems: This cylinder provides seamless, smooth movement which is beneficial in delivering sensitive goods easily.

- Packaging machinery: In packaging machinery this cylinder gets used for its precise motion and less space consumption.

Guided cylinder

In this cylinder guides and bearings are used which ensures more controlled movements and reduces side load easily. These are popular for smooth movements and longer movements with continuous movement. They don’t face misalignment issues easily and are very precise. Only issue with them is that they are bulkier and costlier than other cylinders.

- CNC machinery – In CNC machines these cylinders are used because they are more precise and effective for controlled movements.

- Industrial presses – In presses with more work and higher need of faster outputs these cylinders are more preferred.

Factors to choose when considering pneumatic cylinders

Application requirements: You should be clear on your use of a cylinder. Whether you require force, or higher load capacity you should opt for a working pneumatic cylinder. If you want better stroke length and speed then you should use a rodless or guided cylinder. Space: If you have less space then you should opt for compact designs like rodless or compact cylinders which are built for these applications. Environment: Environment conditions on which cylinder has to work on should be kept in mind and also consider factors like exposure to moisture and dust, and required durability for the cylinder.

Conclusion

Pneumatic cylinder selection now might not be as confusing as before. Selecting the right cylinder per its use can elevate your industrial performance to new heights. You can choose from single acting, double acting, rodless, compact or guided cylinders. It depends on the work you have for the cylinder and your investment budget. Top quality and durability of a cylinder should always be kept in mind as industrial use and workload can be rough with harsh environments. VSpneumatics present to you with all your pneumatic needs.